أهلاً بالعالم !

20 October، 2019FLAMIC

24 October، 2019

Quality Bakery Equipment

Since more than 30 years ago, Ciberpan develops state-of-the-art technology to create bakery equipment that enables producers to manufacture the best bakery product

Tubular rounder

FOR PIZZA AND BREAD DOUGH

The tubular rounder is suitable for bread and pizza doughs, it rounds perfectly to get a ball shaped dough. It is an extremely robust machine, simple and easy to use and maintain. It is an indispensable tool for bakeries and pizzerias since it facilitates the work and reduces considerably. There are two available models:

- Mini– For dough from 30 to 280g

- Maxi– For dough from 200 to 800g

TUBULAR ROUNDER MINI SIZE

The Tubular Rounder Mini Size is suitable for bread and pizza dough from 30G to 280G. It is an extremely robust machine, user friendly and easy to maintain. It is a machine extremely robust, user friendly and easy to maintain. It is also an essential tool in bakeries and pizzerias as it reduces the workload considerably.

- TECHNICAL DATA

- LENGTH:- 580 mm

- HEIGHT:- 800 mm

- WIDTH:- 320 mm

- WEIGHT:- 60 Kg

- VOLTAGE:- 230/400 V

- POWER:- 0.37Kw

TUBULAR ROUNDER MAXI SIZE

Our Tubular Rounder Maxi Size works perfect for bread and pizza dough from 200g to 800g. It is a machine extremely robust, user friendly and easy to maintain. It is also an essential tool in bakeries and pizzerias as it reduces the workload considerably.

- TECHNICAL DATA

- LENGHT 500 mm

- HEIGHT 850 mm

- WIDTH 400 mm

- WEIGHT 75 Kg

- VOLTAGE 230/400 V

- POWER 0.37Kw

Conical rounder

FOR BREADS WITH A ROUNDED SHAPE

The Ciberpan conical rounder is the right machine to obtain breads with a nice round shape.

All versions of Ciberpan’s conical rounders have been carefully designed to guarantee perfect results on a wide variety of bread rolls also for soft dough, without altering the texture of the dough or distorting the final shape. All our conical rounders are equipped with teflon-coated aluminium channels, adjustable flour duster, non-toxic nickel or teflon-coated cones. Our production includes the T1 and T2 versions which can be used in conjunction with the Long-loaf Moulder TS or the “Gemini” double-cone Rounder. The “Gemini” doublecone Rounder has the same characteristics of a single cone machine (even the overall dimensions), but its productivity is doubled because the process does not require any further manual handling. A special arrangement of the two conveyor belts causes the seal of dough to face down when entering in the second cone. Like the rest of the Ciberpan manufactured equipment, they comply with EU directives on safety and hygiene.

CONICAL ROUN D ER 300/310

- T1 pieces from 100/150 to 2000 g approx.

- T2 pieces from 300 to 3900 g approx.

- Teflon-coated aluminium channels

- Adjustable flour duster

- Non-toxic nickel or teflon-coated cone

- Rounding channels length: 4 mt approx

- Dough entry: 830 mm

- Dough exit: 890 mm

- Mounted on wheels

- Installed power: 0,8 kw/ with air blower unit 1,5 kw

CONICAL ROUN D ER 590/600

- T1 pieces from 100/150 to 2000 g approx.

- T2 pieces from 300 to 3900 g approx.

- Double conveyor belt

- Teflon-coated aluminum channels

- Adjustable flour duster

- Non-toxic nickel or teflon-coated cone

- Rounding channels length: 7,3 mt approx.

- Dough entry: 1150 mm

- Dough exit: 750 mm

- Mounted on wheels

- Installed power: 0,8 kw/ with air blower unit 1,5 kw

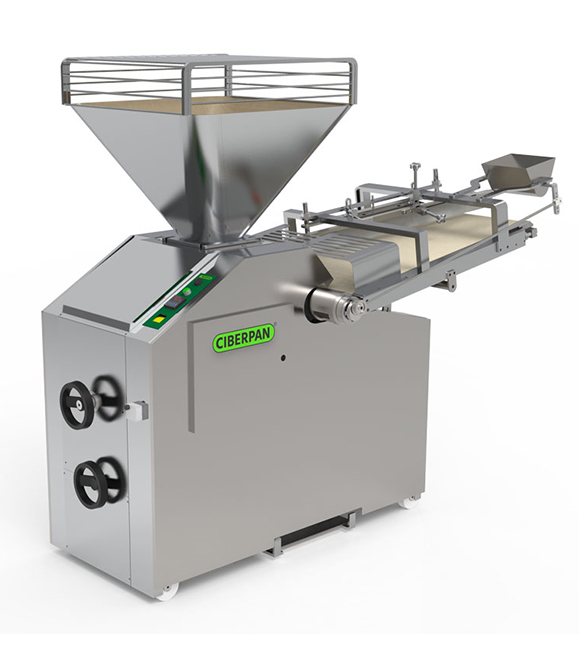

Divider model 93

THE STRONGEST ONE, READY TO WORK 24H / DAY

The divider model 93 from Ciberpan is an accurate and robust machine. Its function is to divide the bread dough in portions with the desired weight. It is a volumetric divider. The dough is absorbed by a piston, after it is compressed and expeled. This systems offers a good weighing accuracy.Multiple piston dividers

When it is needed a high production, the dividers are made with multiple pistons, in such a way that for each cycle of work we can get 2, 3, 4 or 5 dough pieces at a time, so the production of the machine is multiplied. However, in these dividers the maximum diameter of the pistons is limited depending on the number of pistons.

| Weight range (for fresh dough, without fermenting) |

| ∅ Piston (mm) |

Min (g) |

Max (g) |

| 40 |

15 |

150 |

| 60 |

20 |

200 |

| 80 |

25 |

300 |

| 90 |

30 |

400 |

| 110 |

50 |

600 |

| 120 |

80 |

950 |

| 135 |

140 |

1300 |

| 150 |

200 |

1700 |

| Multiple piston productivity |

| Pistons |

Pieces/hour |

Max (g) |

| 2 |

4.800 |

400 |

| 3 |

7.200 |

300 |

| 4 |

9.600 |

200 |

| 5 |

12.000 |

200 |

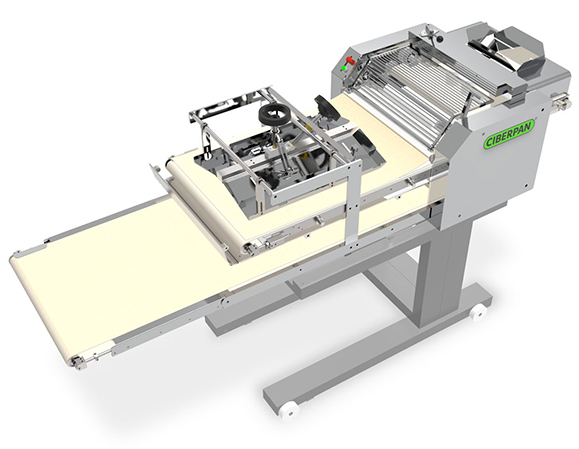

Moulder model F25-CR

FOR TIN BREAD AND HOT-DOG BREAD

The moulder model F25-CR is specifically designed to produce tin bread, roll bread and also hot-dog bread.

Proofer C93

STATIC INTERMEDIATE PROOFER

The intermediate proofer model C93 is an accurate and reliable machine, with so reduced size that it passes totally erected through a standard 2,10 m height and 0,8 m width door.

Its function is to give the necessary resting time to the recently divided dough portions, in order to let them lose the tensions acquired in that process and ease its lengthing in the next step of the productive process: the forming.

| Capacity according to models |

| Model |

Capacity (n. pieces) |

| C93E |

177 |

| C93E + 1A |

243 |

| C93A |

276 |

| C93A + 1A |

345 |

| C93A + 2A |

414 |